News

Site Editor

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Laser cutting uses a highly concentrated stream of photons to cut precise designs in sheet metal. Laser cutters like ours are programmed using Computer Aided Design (CAD) software providing high levels of accuracy to every cut as we programme each variable (metal thickness, type and subtype, speed of cut and laser intensity ratios) into our software for the laser to action in cutting the sheet metal.

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Laser cutting uses a highly concentrated stream of photons to cut precise designs in sheet metal. Laser cutters like ours are programmed using Computer Aided Design (CAD) software providing high levels of accuracy to every cut as we programme each variable (metal thickness, type and subtype, speed of cut and laser intensity ratios) into our software for the laser to action in cutting the sheet metal.

Fiber Laser Cutting vs. Traditional Sheet Metal Cutting

Views: 489

Author: Site Editor

Publish Time: 2021-11-05

Origin: Site

Fiber Laser Cutting

Laser cutting uses a highly concentrated stream of photons to cut precise designs in sheet metal. Laser cutters like ours are programmed using Computer Aided Design (CAD) software providing high levels of accuracy to every cut as we programme each variable (metal thickness, type and subtype, speed of cut and laser intensity ratios) into our software for the laser to action in cutting the sheet metal. With the automation of the laser cutting itself and the installation of an automatic feeder shuttle table for the metal, we can run sheet metal through the process without having to constantly monitor the machine, allowing large volume work to be completed over night with the machine left unattended.

Our laser cutting machine cannot be used to cut plastics (they melt), wood (it burns) or metals that are considered to be “shiny” when molten – meaning that they have a low melting point and melt under the photon beam of the laser, like brass and copper. This is not to be mistaken for “polished” as we can cut mirror polished stainless steels. For these materials the alternative cutting methods are more suitable – such as waterjet cutting or mechanical cutting (using a band saw, for example). Our laser cutter also cannot be used to cut tubes, we have a band saw for that!

There are 3 main types of laser cutting, each with their own advantages and disadvantages. Generally speaking the advantages of laser cutting as listed above are accuracy, speed and affordability, and the disadvantages are the limitations on material thicknesses and types. Let’s take a closer look at how laser cutting compares with other cutting methods.

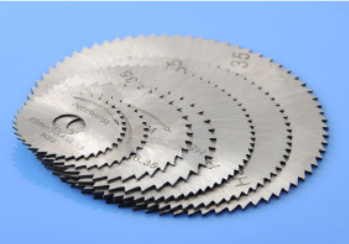

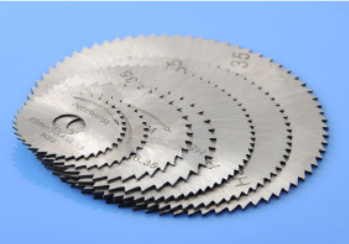

Mechanical Cutting

Mechanical cutting or milling on CNC or manual machines can create parts in countless shapes and configurations and in 3 dimensions. Using machines like lathes, mills, boring bars, and other parts can be made with steps, perfect angles, drilled and tapped holes, beveling, and radii. In many instances all of these steps can be performed on one machine. These CNC and manual mills can also hold incredibly tight tolerances within 1/10 of 1/1000th of an inch with proper techniques and tooling.

Milling machines like lathes and CNC mills are used for parts that have a complex shape and require very tight tolerances. Round objects like hubs, shafts, rollers, and cylindrical objects need to be machined on a lathe. Square or more complex shaped objects with stepping and holes that are three dimensional should in most cases be milled on a CNC or manual mill. In some cases these parts can be cut out on a laser at larger than specified dimensions and then trimmed and cut down on a CNC mill to the exact dimensions and this is done in custom fabrication and machining frequently.

Plasma Cutting

Used only on metals, plasma cutting can cut through thick sheets that a laser can’t. The plasma arc cutting process uses electrically conductive gas to transfer energy through the plasma cutting torch to the metal being cut. Like laser cutting, a plasma cutter cannot cut through plastics or woods, but like the waterjet it can cut through thick metals. Also like the laser, plasma melts the metal to pierce through it and has a high level of accuracy.

while laser cutting and plasma cutting share a great many similarities in process and precision, tolerances, energy consumption and required protection of laser cutting is considerably lower, making this method superior in the industrial field of sheet metal cutting.

Which one is the best?

The reliability of laser in its precision cutting and CAD programming is our primary reasoning for providing this service as the main part of our profiling portfolio. We chose laser over all other cutting methods because for us and for our customers, it is the best choice. And with fibre lasers now available it is an ever growing and evolving method of cutting. If you are looking for a fiber laser cutting machine, please contact us immediately!